The Science Behind Load Distribution in Lifting Operations

In heavy lifting operations, understanding the science of load distribution is paramount. Effective load balancing not only ensures safety but also enhances operational efficiency. This blog delves into the physics behind load distribution, explores the principles of safe lifting techniques, and highlights their applications across industries.

What is Load Distribution?

Load distribution refers to the even spreading of weight across a lifting system to prevent strain on any one component. In lifting operations, uneven loads can cause equipment failure, accidents, and damage to the items being lifted. Understanding and applying the principles of load distribution are essential for achieving stability and minimizing risks.

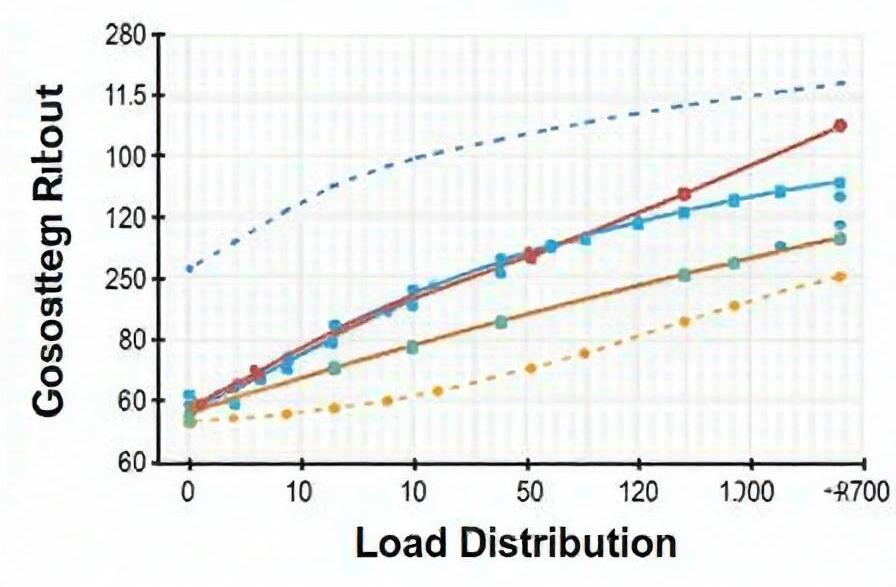

The Physics of Load Balancing

Center of Gravity (CoG): The CoG of an object is the point where its weight is evenly distributed in all directions. Identifying and aligning the CoG with the lifting point is crucial for stable operations.

Forces and Leverage:

Tensile Forces: Lifting equipment like slings and cables experience tensile forces when bearing loads. Proper distribution reduces undue stress on these components.

Moments and Torque: Uneven loads create torque, which can destabilize lifting equipment. Equal force distribution counteracts these destabilizing effects.

Load Angles:The angle at which a load is lifted affects the amount of force exerted on lifting equipment. Wider angles distribute forces more evenly, whereas sharper angles concentrate stress.

Safe Lifting Techniques

Pre-Lift Planning:

Conduct thorough assessments to determine load weight, size, and shape.

Identify the CoG and ensure alignment with the lifting mechanism.

Using Load Balancing Equipment:

Spreaders and Beams: Essential for distributing weight evenly across multiple lifting points.

Adjustable Slings: Allow for flexibility in handling loads of different sizes and shapes.

Monitoring During Lifting:

- Utilize load-monitoring systems to detect imbalances in real-time.

- Communicate effectively among team members to ensure coordinated operations.

Regular Equipment Maintenance:

- Inspect slings, spreader beams, and lifting mechanisms for wear and tear.

- Adhere to manufacturer guidelines for proper use and maintenance.

Applications of Load Balancing Techniques

Construction: Ensuring safe lifting of beams, precast concrete, and structural components.

Shipping and Logistics: Loading and unloading heavy cargo while maintaining stability.

Energy Sector: Handling turbines, pipelines, and other critical infrastructure.

Manufacturing: Safely moving machinery and production molds.

The Benefits of Proper Load Distribution

Enhanced Safety: Minimizes risks of accidents, injuries, and equipment failure.

Operational Efficiency: Reduces time and effort needed for lifting tasks.

Cost Savings: Prevents damage to equipment and lifted materials, saving repair and replacement costs.

Compliance with Standards: Meets safety regulations and industry best practices.

Conclusion

Mastering load distribution is both a science and an art, requiring a blend of technical knowledge and practical expertise. By understanding the principles of load balancing and incorporating safe lifting techniques, industries can achieve safer and more efficient operations. Investing in training, high-quality equipment, and proper planning is key to reaping the benefits of effective load distribution.

Have a Project? Let’s Talk!

TESTING FACILITY